ThermoSim as a spring contacts simulation model

A spring contacts simulation model is a digital tool for performance forecasting of spring contacts. The customizable spring contacts simulations assist in optimizing technical processes. Potential errors are identified early, and the performance of the contacts is automatically improved without the need for physical prototypes.

Temperature analysis of spring contacts for your specific application

ThermoSim is a spring contacts simulation model developed in collaboration with the "Center for Heat Management" (ZFW). This temperature simulation is based on the modeling of RC components. The ThermoSim simulation model identifies temperature-critical points of the spring contact pin using customer-specific load profiles. By assuming your specific current and load cycles in the simulation model, it is possible to make predictions about the expected temperature responses at the relevant contact points. These are graphically represented using ThermoSim.

We currently offer ThermoSim for the following high-current contact pins:

WHAT ARE YOUR BENEFITS FROM THERMOSIM?

- Fast and efficient verification of load cycle changes or new load profiles

- Avoidance of prototyping costs

- Shorter development times

The Role of Heat Management Simulation in the Performance Analysis of Spring Contacts

In modern electronics, spring contacts are crucial for the reliability and efficiency of connections. A heat management simulation is essential to identify potential heat issues early and reduce overheating. Excessive heat can, in the worst case, lead to material fatigue and wear. With a precise heat management strategy, your spring contacts can operate under optimal conditions, extending their lifespan and enhancing the efficiency of your system.

What are your benefits from ThermoSim?

- Quick and efficient verification of load cycle changes or new load profiles

- Avoidance of prototyping costs

- Shorter development times

For the customizable spring contacts simulation of your high-current applications, we need the following information:

- The ambient temperature

- The electrical load profile

- Contact material of the counterpart

- Installation situation of the Pogo Pin

Details Regarding Your Electrical Load Profile

We specifically need the different current loads and the duration of current flow for your specific application. Of course, we are happy to advise you to ensure we can present the most accurate result possible.

Your Direct Connection to Our Experts

Providing our customers with the best possible advice is important to us!

That’s why we gladly offer you personalized consultation:

To get in direct contact with our experts, feel free to reach out via email at ThermoSim@fixtest.de . Our team is ready to assist you with all inquiries related to "thermal simulation." Of course, as with any other topics, we are also available for phone consultations at +49 (0)7733 5056-0.

Current-load cycles simulation model: How are load tests conducted?

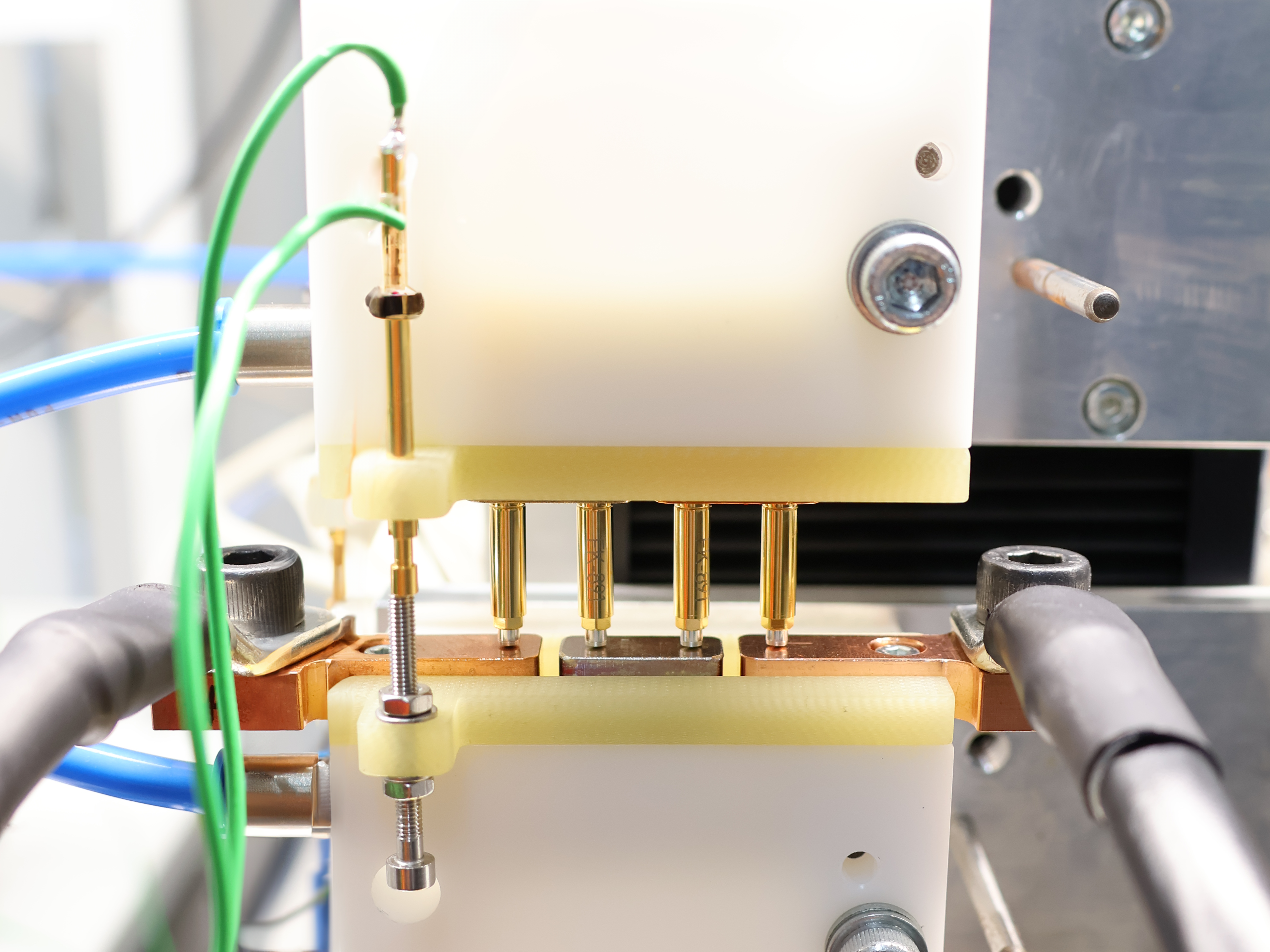

The image on the left shows which "temperature-critical point" is considered in the customizable spring contacts simulation. The contact points particularly affected by heat generation are explicitly examined. In the adjacent example, you can see the "lens head." Both the simulation-capable FK-891 and the FK-133 are equipped with this feature.

Using the temperature analysis simulation model for spring contacts, the temperature developments relevant to your specific application can be represented.

The test bench shown below was used to verify the results during the development of the spring contacts simulation model, ensuring that ThermoSim provides precise and stable outcomes. Through our cooperation with the "Center for Heat Management" (ZFW) for this project, we were able to achieve the best possible modeling simulation results.